Product Description

Production description

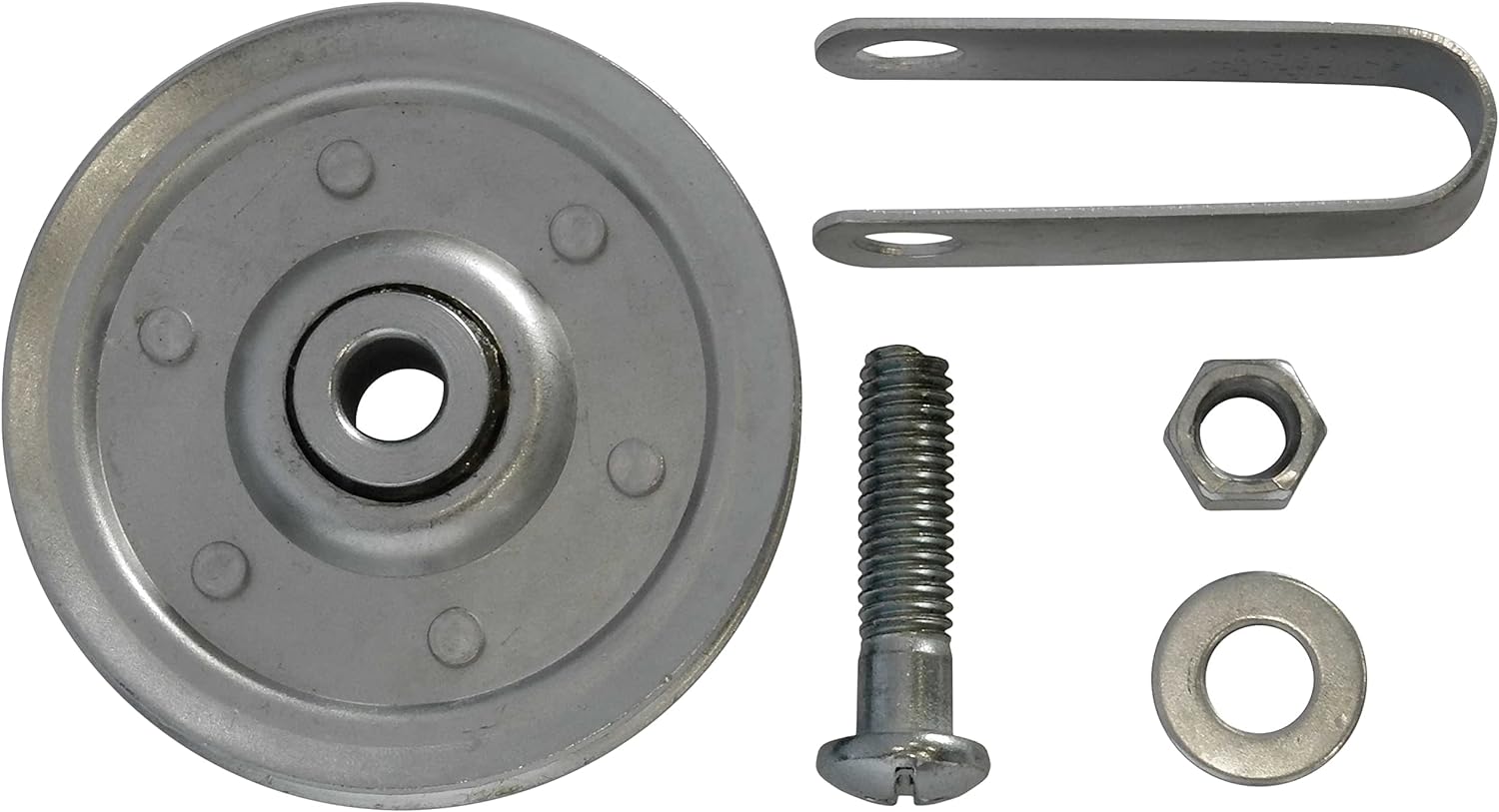

Outdoor Power New Parts Idler Idler Pulley Replaces

- ID: 3/8″ | OD: 4 7/8″ | Height: 1-1/8″

- Compatible with MTD 38″, 42″, 46″ and 54″ Decks

- Compatible with Cub Cadet Parts: 756- 0571 9B, 756- 0571 9C, 956- 0571 9, and 956- 0571 9C

- Compatible with MTD Parts: 753-5711, 756- 0571 9B, 756- 0571 9C, 956- 0571 9, and 956- 0571 9C

Our advantages: Focus on the stamping/welding/bending of the metal parts for automotive and construction application more than 30 years.

Leading Equipment:welding robots ,continue gas stations,CNC machining centers,CNC pipe bending machines,laser cutting machine.

Inspection Equipments:CMM,Five Elemental Analyzers, Salt spray test machine,Tensile testing machine.

We now have 100 customers from all over the world.

1. We have own factory and 80% of staff in our company worked for more than 10 years.

2. We provide a competitive price.

3. High precision, tolerance can be within ±0.01mm.

4. 14 years’ export experience.

5. Small order also is welcomed.

6. We can also provide one-stop service, including mold and assembly.

7. NDA apply to all customers.

| Mold Material | DC01,DC04,DC06 |

| Tooling life Time | 100K times |

| Tooling Material | 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper |

| Surface Treatment | Anodized, powder coating, lacquer coating, black oxide |

| Salt and spy test | From 72-480 h |

| Size | 1) According to customers’ drawings 2) According to customers’ samples |

| Drawing Format | step, dwg, igs, pdf |

| Certificates | ISO 9001:2015 & IATF 16949 |

| Payment Term | T/T, L/C, Trade Assurance |

New Project Product Development Process

According to APQP process develpment plan from TS 16949 Quality Management System.

Raw Material Warehouse

Prepare the raw material according to customer delivery schedule and carry out FIFO exactly by ERP system.

Raw Material Chemical Element

Mechanical PropertiesTest Before Production ,the first step of the quality control.

Stamping Workshop

Overview of the Stamping workshop with cover the

Stamping equipment from 100T to 800T.

Hydraulic Press cover from 50T to 3100T.

With the mold(die,tooling) produce by ourselves we can customize all kinds of metal shape according to customer drawing call out.

Bending Workshop

CNC bending machine with servo control precise control the tolerance according to customer requirement.

The capacity of bending diameter reach to Φ135mm.

Welding Workshop

Welding robot with Synchronous workstation introduce from CHINAMFG Japan ,we had 23pcs welding arm with 64 pcs working stations,sheild welding support by Continuous gas supply station.

Brazing Welding For Pipe

Pipe with brazing welding can get perfect out appearance also reduce leaking on welding area.

Spot Welding (Resistance welding)

The ABB resistance welding robot can improve the welding joint strength also Improve spot welding efficiency.Reduce defects of traditional spot welding.

Surface Treatment

The coating line improves the efficiency, reduces the pollution to the environment, and the wastewater discharge after industrial treatment reaches the national standard.

Mold Workshop Warehouse

We can design and manufacture molds according to customer requirements,2500 square meter special for stamping mold warehouse.

Tooling Prepare

We simulated the workpiece by J-STAMPING software ,then we design the mold for metal sheet part ,not only it short the leadtime for development but also saving the cost for customer.

Gantry CNC machining center

The capacity of the CNC machining center can reach 3200*2500*1000mm,the tolerance can reach 0.008mm after test by CMM and Handy scHangZhou equipment.

Dimension Inspection

The mold and inspect gauge also the PPAP part was inspect by the CMM and Handy scHangZhou equipment.

ERP System In Our Company

All data support by ERP System, Cover From Raw Material Incoming To Shipment.

Customer Audit

* Evaluate the quality of customer service.

* Compare the quality with previously established goals.

* Identify gaps for improvement.

* Find ways to improve customer service.

* Gather all of the required data with Live Agent.

* Check activities.

Company Team

Team Working Together For Bright Future

ENJOY THE WORK, ENJOY THE LIFE.

Cooperative Partner

Thanks To Ford, CHINAMFG Moters, Toyota,CAMSD,FAW-VOLKSWAGEN, HONDA,JMC.

FAQ:

| 1. Do you provide samples? is it free or extra? |

| Yes, we can offer the sample for free charge but do not pay the cost of freight. |

| 2. How about the shipping cost? |

| The cost of shipping depends on the method you choose to obtain the goods. Express delivery is usually the fastest method, but it is also the most expensive method. Shipping is the best solution for large quantities. For the exact shipping cost, we can only provide you with detailed information after knowing the quantity, weight and dimension. |

| 3. Do you have Stock productions to sell? |

| Yes, of course. But we also offer OEM service. The mold is customized, Please send us some drawing. What information do you want to know if i want to get a quotation? a). The application for your products. b). Special package methods if you needs. |

| 4. Do you inspect the finished products? |

| Yes. Each step of products will be carried out inspection by QC department until shipping |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type C |

| Manufacturing Process: | Forming |

| Samples: |

US$ 32.5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do garage door pulleys contribute to the smooth and controlled movement of the door?

Garage door pulleys play a crucial role in ensuring the smooth and controlled movement of the door. Here’s how they contribute to this process:

1. Cable Guidance:

Garage door pulleys provide a guided path for the lifting cables. As the cables extend from the bottom corners of the door, they pass through the pulleys, which keep them aligned and prevent them from deviating from their intended path. This guidance helps prevent the cables from becoming tangled or snagged during door operation.

2. Friction Reduction:

The pulleys are designed with a low-friction surface, typically a smooth and durable material such as metal or plastic. As the lifting cables run over the pulleys, this low-friction surface minimizes friction and reduces resistance, allowing the door to move up and down more smoothly and with less effort.

3. Even Weight Distribution:

Garage door pulleys help distribute the weight of the door evenly across the lifting cables. This even weight distribution reduces strain on individual components and ensures that the door moves in a balanced manner. It helps prevent excessive stress on the cables, springs, and other parts of the garage door system, promoting smooth and controlled movement.

4. Tension Maintenance:

The pulleys assist in maintaining proper tension in the lifting cables. By supporting the cables and guiding their movement, the pulleys help keep the cables taut and balanced throughout the door’s operation. This consistent tension is essential for smooth and controlled movement, as it prevents slack or uneven pulling of the cables.

5. Reduced Vibrations:

Well-functioning garage door pulleys can help reduce vibrations during door operation. The smooth and controlled movement facilitated by the pulleys minimizes the occurrence of jerky or erratic motions that can lead to vibrations. This contributes to a quieter and more stable operation of the garage door.

6. Enhanced Safety:

By ensuring smooth and controlled movement, garage door pulleys contribute to the overall safety of the door system. Smooth operation reduces the risk of sudden jolts or unexpected movements that could pose a safety hazard. Additionally, proper tension maintenance and weight distribution help prevent cable slack, imbalance, or detachment, reducing the likelihood of accidents or malfunctions.

In summary, garage door pulleys contribute to the smooth and controlled movement of the door by providing cable guidance, reducing friction, maintaining even weight distribution, assisting in tension maintenance, reducing vibrations, and enhancing safety.

editor by CX

2024-01-23